Brief Introduction of the LED Strip Production Process

The 2018 new year is coming , hope everyone have a very nice new year holiday!!!

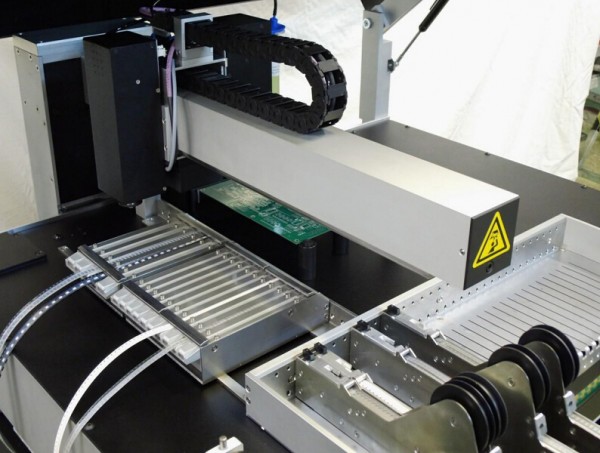

Secondly,before we put the pcb into SMD machines to make chip on board , we must make tin silking on PCB board, so that the led chip can be connected very well with the pcb .

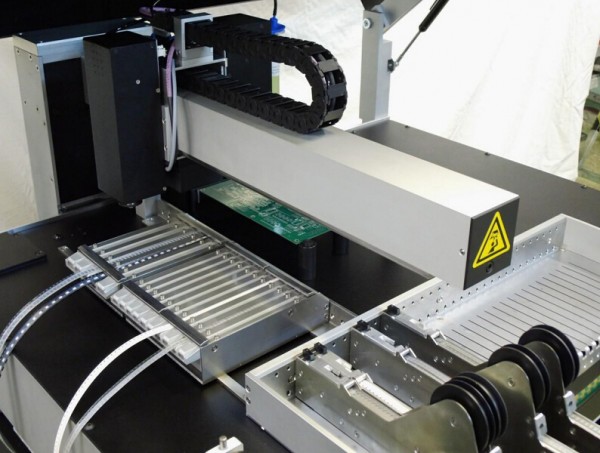

Thridly, after the led chip on board in smd machines, we will put led strip to the reflowing soldering machine to make led chip connected fasten and better to PCB board , it is also a very important procedure to make tin and led chip on pcb try enough.

Today I would like to have a brief introduction about the production process of LED strip light for everyone.

Firstly, before we use the led chip , we must make it dry enough in the oven, why we do this procedure? It is because the led chip will easily be damaged when they get wet.only in this way , so that we can gurantee the good quality of led chip.

Secondly,before we put the pcb into SMD machines to make chip on board , we must make tin silking on PCB board, so that the led chip can be connected very well with the pcb .

Thridly, after the led chip on board in smd machines, we will put led strip to the reflowing soldering machine to make led chip connected fasten and better to PCB board , it is also a very important procedure to make tin and led chip on pcb try enough.

Fourth, after this process , we will see there are every half meter (0.5m) led strip come out from the reflowing soldering machine, then we will join each 0.5meter together to 5 meter . So now , the led strip is early to finish.

The last procedure is , we will make dc connectors or red/black wire on the end of led strip . the last but not the least is : we will take 24 hours – 48 hours to make aging test before packing to ship .

We are the professional led strip manufacture for the elevator shaft , so If you have any problems or needs with high voltage LED strip for the shaft lighting, please send us a message, we will be happy to hear from you and provide the right products you need.

We are the professional led strip manufacture for the elevator shaft , so If you have any problems or needs with high voltage LED strip for the shaft lighting, please send us a message, we will be happy to hear from you and provide the right products you need.

Previous:Elevator Lighting